Riedon Blog

Welcome to the Riedon Blog. Here you will find articles and resources related to all types of resistors and shunts.

PCN for Shunts and Fuse Blocks

In order to consolidate the manufacturing processes within Bourns, effective April 30, 2024, Bourns will relocate the manufacturing site for select Bourns® Shunts and Fuse Blocks from the Tecate, Mexico facility to the Heredia, Costa Rica facility. As shown below, the...

Bourns Acquires Assets of Riedon, Inc.

Exciting news! 🎉 I'm thrilled to share that Bourns, Inc. wholly owned subsidiary, BE Services Company, Inc, has acquired substantially all of the assets of Riedon Inc. This incredible opportunity will enable us to leverage their resources, expertise, and...

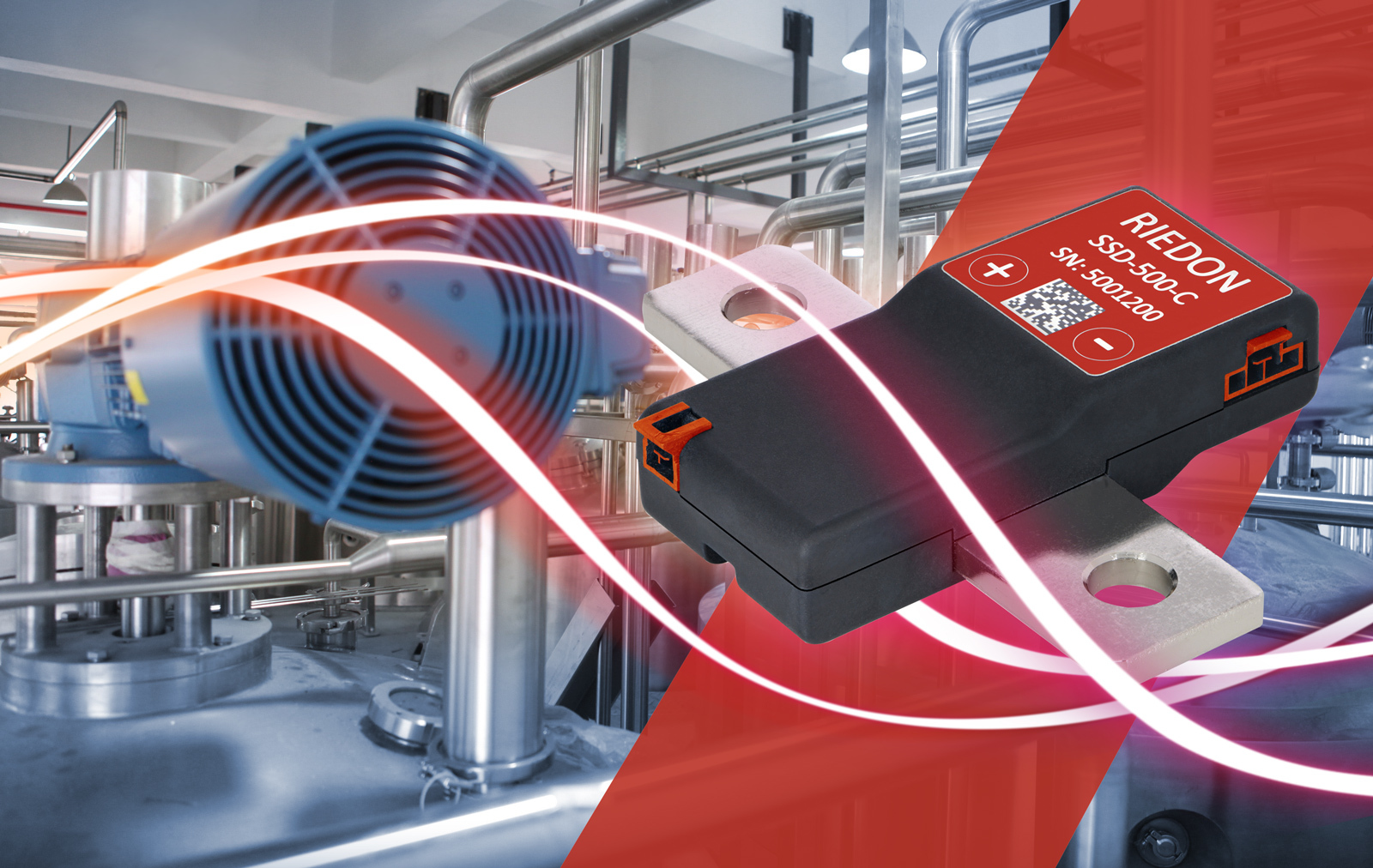

Electronic Design Features Riedon’s DC Current Sensors

Here is a quick summary of their article: Riedon Inc., a specialist in power and precision resistors, has introduced its new SSD Smart Shunt series of digital DC current sensors. These sensors offer high accuracy, energy efficiency, and rugged design, making them...

EEWorld Online Features Riedon

Here is a quick summary of their article: Riedon Inc. has introduced the SSD Smart Shunt series, a board-level current sensor featuring a 16-bit automotive-grade microcontroller unit (MCU), a 24-bit ADC, and a flash memory resource. These highly-integrated digital...

Riedon SSD Smart Shunts Featured on Design World

Here is a quick summary of the article from Design world featuring our SSD Smart Shunt Series. Riedon Inc., known for its expertise in power and precision resistors, has unveiled the SSD Smart Shunt series, a major product innovation following the success of its SSA...

Riedon is featured on major websites

We are delighted to announce the launch of our latest product line, the SSA Smart Shunt current sensor series. The industry's response has been exceptionally positive, with numerous prominent companies showcasing our innovative SSA Smart Shunts on their websites to...

Norwegian Based Elektronikknett Features Riedon SSD Smart Shunt series

Riedon Inc., a specialist in power and precision resistor manufacturing, has recently launched a significant product innovation following the success of their SSA Smart Shunt current sensor series. The new product line, known as the SSD Smart Shunt series, comprises...

Press Release – Riedon Unveils Digital DC Current Sensors – Making Current Measurement Even Easier

Published: https://www.powersystemsdesign.com/articles/riedon-unveils-digital-dc-current-sensors-making-current-measurement-even-easier/90/19905 Date: 3/29/2023 Following the market traction achieved by its SSA Smart Shunt current sensor series, specialist power and...

Shunt Accuracy Questions

Question From Client: We have recently ordered multiple shunts from Riedon, and we are happy with the products. I have some technical questions regarding the scaling. For instance, we have a shunt Model: MKB450/50mv . When I look at the resistance table on your...

Riedon’s DC Ammeter shunt cross to Murata Shunt

This is a list of Riedon part numbers and their corresponding part numbers for Murata. Riedon Part No Murata Part No RSA-10-100 3020-01107-0 REVB RSA-100-100 3020-01108-0 REV C RSA-100-50 3020-01099-0 REV C RSA-150-50 3020-01100-0 RSA-20-50 3020-01098-0...