Metal foil resistors offer unmatched performance for the highest precision applications, without compromising on accuracy, stability or speed. They are constructed by adhering a metal alloy foil, usually nickel/chromium (Nichrome) with some additives,to a ceramic base. Typically this foil is a few microns thick. A pattern is then photo-etched into the foil to trim the resistance to the correct value. Foil resistors can be made in chip/SMD or leaded/through-hole packaging.

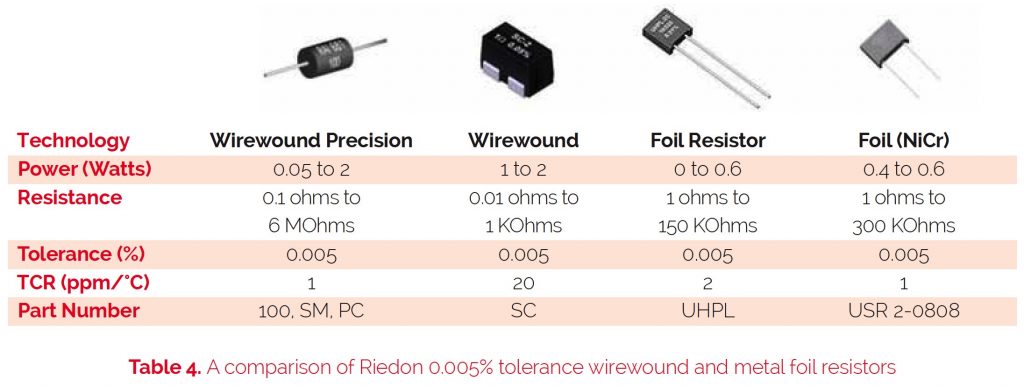

Compared to other resistor technologies, foil offers low TCR, the best long-term stability of all resistor technologies, non-inductance, ESD immunity, low capacitance, fast thermal stabilization, and low noise. For example, Riedon’s UHPL series of through-hole foil resistors achieves tolerance of ±0.005%, a TCR of ±2ppm/°C and a load life stability of ±0.005%. Meanwhile, the ultra-high precision, surface mount UHPC series achieves an extremely low TCR of ±0.05ppm with a power coefficient of 5ppm/W at rated power and a load life stability of ±0.005%.

Temperature Coefficient of Resistance

Low TCR is one of the foil’s most important properties for applications like precision analog circuits that require tight temperature stability. This is down to the properties of the foil itself; as the temperature rises, the resistance of the foil rises, but the temperature increase also causes compressive stress on the foil (due to differences in the coefficient of thermal expansion of the foil and the base), which reduces the foil’s resistance. Overall, the balance of the two effects leads to a very stable resistor. TCRs of ±0.05ppm/°C or less are available with today’s technology, such as Riedon’s USR 2-0808 series. Foil products also exhibit a low power coefficient of resistance, that is, they exhibit low self-heating due to the power they dissipate, which adds to their temperature stability.

Thermal Stabilization

Thermal stabilization is a measure of how quickly the device’s resistance stabilizes when exposed to a change in temperature, whether that’s a result of ambient temperature changes or self-heating due to an increase in power dissipation. This is important in precision circuits which require the highest possible stability. Foil resistors are a clear winner over other technologies in this case, stabilizing within a few seconds, while other technologies’ response is in the order of minutes.

Response Time

As well as temperature-related effects, the nature of foil resistors means they also have minimal parasitic inductance and capacitance. This is critical in circuits that rely on high-speed signals as any unwanted inductance and capacitance distort and degrade the signal. Compared to wirewound resistors, which are in essence a coil of wire and therefore have a parasitic inductance, the patterned metal foil that foil resistors use is all in one plane. The foil patterns are also specially designed to mitigate any parasitic reactance; S-shaped or zig-zag patterns mean current in adjacent wires flows in different directions. A good design can replicate pulses as short as a few nanoseconds on the output. Foil resistors are therefore suitable for high-frequency applications.

Applications

Applications for foil resistors include anywhere that high precision and excellent long-term stability is required, including high precision instrumentation and differential amplifiers. They are popular in audio circuits since the increasing demand for sound integrity places noise restrictions on components in order to preserve signal integrity. Medical devices, automated test equipment, current sensing and weighing systems commonly use foil resistors.

They also suit military and aerospace applications, extreme environments such as downhole drilling and the industrial sector.